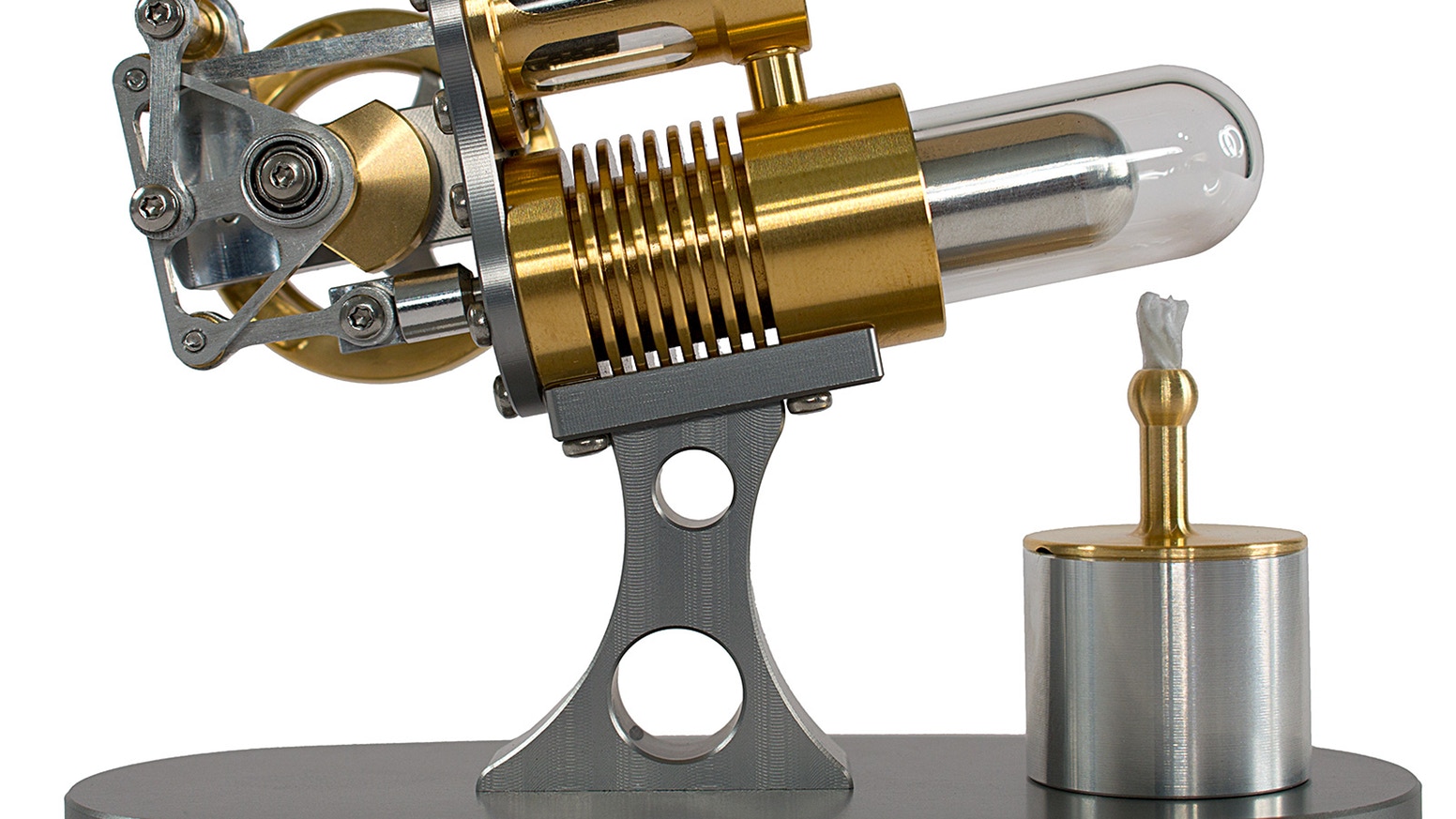

Version Stirling engines are fascinating and entertaining to build…but they could be difficult to understand. If you’re considering product Stirling engines but aren’t certain precisely what they may be (or why they’re so excellent), this post will answer a few of your queries.The Stirling engine is known as for its inventor, Robert Stirling. It really is a shut down-cycle regenerative heat engine. It operates by cyclically compressing and growing air or any other petrol (known as the operating substance) at diverse temperature ranges. The high temperature vitality created helps to make the engine run.

A Stirling engine is undoubtedly an external combustion robot telecommande, similar to a water vapor engine. Because of this every one of the engine’s warmth should go inside and out throughout the wall surface of your engine, from an outside source of heat. But unlike a heavy steam engine, which utilizes h2o in both water and gasoline kind, Stirling engines use only the gasoline forms of drinks for example hydrogen, helium or o2. This working substance is compressed, warmed, expanded, after which cooled yet again within an continuing pattern.Stirling engines contain a repaired volume of doing work liquid. The engine is enclosed, so no gasoline foliage the engine, and none goes in externally. In case you have a fixed level of gas in a set amount of place, rearing the temperatures of your gas will increase its strain. In the event you compress the gasoline, its temperatures may go up.

The petrol is relocated forward and backward in between cold and hot warmth exchangers. To put it really, a basic Stirling engine performs like this:

- A hot temperature exchanger (a heated up cylinder) is subjected to an external source of heat, which in turn warms the fuel in that cylinder and results in the pressure in the gasoline to enhance. This elevated tension definitely makes the piston inside the warmed tube move lower and really do work.

- The piston on the other side goes up as other movements straight down, and this then drives the warmed gas to the microscope enfant, or chilly tube. The chilly tube is cooled by the background temperature of the encircling setting or by an external supply of frosty. As the gasoline cools down, its stress is minimized plus it becomes simpler to compress.

- The piston in the frosty cylinder then techniques down and compresses the cooled gasoline. Any heat made through the compression is taken off through the cooling supply (referred to as the warmth drain).

- The piston within the heating cylinder moves up, and fuel needs back into the warmed tube. Mainly because it heats up the pressure raises, the piston moves lower, and also the period repeats over and over.

Often a regenerator is put somewhere between the warmed area as well as the air conditioning location. This acts as a heating retail store and boosts the engines effectiveness by retaining and trying to recycle the temperature that passes with the engine, as an alternative to allowing it to lessen.